Case 17: Jim Thompson Thai Silk Company

| 1951 | - Jame Thompson established JT |

| 1967 | - Jame Thompson disappeared in a

Malaysian Jungle resort. - JT board appointed as acting manager an American who had been assistant manager under Mr. Thompson. |

| 1974 | - Bill Booth was appointed

managing director. - JT established a sewing venture in partnership with a prominent Thai Businesswomen. |

| 1979 | - JT entered the weaving business on a wholly owned basis. |

| 1988 | - JT entered into sericulture and spinning on a wholly owned basis. |

| 1992 | - Open the new retail outlets at World Trade Center. |

| 1993 | - The sewing Joint venture operation employed 350 skilled seamstresses to produce more than 500,000 different pieces of merchandise. |

| 1994 | - Design Department employed more than 30 people devoted to developing new fibers, new color formulations, new weave partners, new print designs and new garments. |

For example:

Since the major markets of JT are retail market, home furnishing and export, we will analyze the five-forces model of competition in these three markets.

In 1994, there were dozens of competitors selling high-priced silk and cotton merchandise to foreign tourist in Bangkok. However, the number of such rivals had decreased over the years, and several powerful competitors of an earlier era had almost collapsed. The major competitors at that time were Shinawat, Star of Siam.

There were numerous and highly automated competitors in home furnishing market. The key competition was based on design, price, and delivery.

The rivalry of textile industry especially in silk market was not only in the domestic market. For the world silk market, there were many foreign competitors. India, Malaysia, Bangladesh and Indonesia were the major competitors who captured market share from Thai silk.

There were high barriers for new entrants to three markets.

For the retail market, the brand preferences and customer loyalty is one of entry barriers to this market. Because JT who dominated for premium price market has the reputation on design and quality of Thai silk. It can gain strong brand preference from customer. Thus, a new potential entrant must spend more effort and money to overcome customer preferences.

Another barrier for Thai silk market was an inability to gain access to technology. Very small producers dominated Thai silk industry. To acquire the new technology, it needs high investment.

For home furnishing, it also has many large and highly automated producers. A new entrant to this segment needs high effort to win.

Textile industry consists of many kinds of fabrics which can substitute Thai silk such as Lenin, Rayon, polyester. Almost of them has the attractive price for customers. They also have the comparable quality with silk. Thus, there was quite high availability of substitute products. However, the perceptions of customer to Thai silk were high quality, unique, elegant products which create the competitive advantage over other substitute products.

For domestic market, JT can gain the competitive advantage from suppliers, The reason was that the suppliers of raw material such as raw silk was very small family operations. So they have low bargaining power. Moreover, because JT is only fully-integrated producer of Thai silk. It expanded into production to establish secure sources of supply. Thus, it can control source of suppliers. However, at that time, the supply of raw material in domestic still did not meet the demand. It had to rely on the import raw silk from other countries such as China. Nevertheless, supplier-related competitive pressures tend to be minimal because silk is a commodity available from many suppliers. For the home furnishing market, since there are a large number of suppliers, so they have low bargaining power.

Due to JT’s great reputation on quality and differentiate Thai silk, buyers may “loss bargaining power”

However, for the home furnishing market, buyer has “a strong power” on their purchasing decision. Because there are many competitors served in this market, buyers can switch to other products.

The competitive pressure from buyers in export market can consider as strong. Because there are many competitors around the world, buyers have many choices to select. So they can have high bargaining power.

The driving forces are the important factors causing the change in industry’s structure and environment. There are several dominant forces within textile industry particularly in silk market.

Thai silk, in previous day, dominated by small family operation. Then, JT entered to the market. It shook up competitive condition. Native silk has become the commercial attraction. Design and quality are the key competitive factors. Thus, the number of such rivals had increased

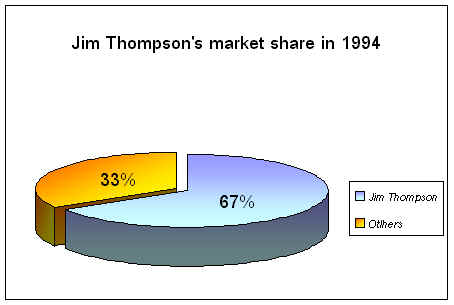

However, when the environment has changed affecting the profitability of these firms, many major companies could not survive in the business and exited from this market. Thus, it changes competitive structure by reducing number of competitors and increasing the dominance of JT market leader, commanding an estimated two-thirds of the entire premium market.

In the case of China, where produced more than half of the world’s raw silk output, the Chinese government had long encouraged silk production. But in the 1980, they had changed the policy to allow silk producers to cultivate other lucrative crops. This policy changing had affected the reduction on output of silk. Thus, it increased price of silk and leading remaining producers to skirt official channels and sell their output at elevated prices through Hong Kong’s black market.

In the case of Thailand, due to the increasingly stringent water pollution regulation in the Bangkok area, it influenced to the decision making on new plant location of such JT. The way in operation more carefully to meet the regulation.

3. Changing lifestyle

According to the changing lifestyle of people especially in Bangkok, this created the opportunity to expand to new market. When it has had the serious traffic congestion in Bangkok, people have changed their lifestyle to stay in downtown condominium near their work locations. Shifting the people lifestyles affects to they players to response quickly and pays attention to cotton fabric using in home furnishing market.

4. Diffusion of technical know-how

Technology transfer across national boundaries has emerged as one of the most important driving forces in globalizing markets and competition. Previously, Thai silk was operated by small producers with traditional handicraft method. When the diffusion of technical know-how such as printing and sewing has incurred, it also created the transfer of technology across the nation. For example, JT accessed to this technical know-how through joint venture, training employees abroad and bringing foreign experts. This transfer of technology can help producers to upgrade their manufacturing capabilities in a long-term effort.

5. Changing in macroenvironment and world situation

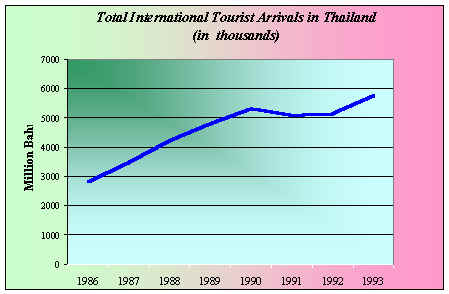

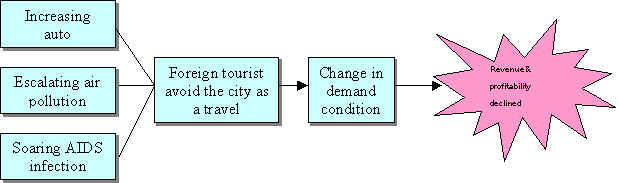

Changing in macroenvironment and world situation can affect the way to operate and market of the industry. Because the majors of Thai silk customers were tourists visited Bangkok and foreigner stationed in Bangkok. So when the macro environment changes in Bangkok such as the increasing auto congestion, escalating air pollution and soaring AIDS infection, it also changes the attitude of tourist to visit Bangkok. Moreover, the world situation such as Iraq war and recession in Japan and Europe caused the reduction for the number of tourists. These are the forces to player to finding the new market method to remain their shares.

| James Thompson |

|

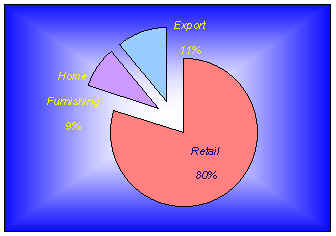

Sales revenues came from three major markets. In 1993 80% of sales revenue came from retail sales, 11% from export, and 9% from home furnishing.

JT was a leading retailer of native silk. Two-thirds of the premium tourist market was captured by JT.

JT unique

JT reputation

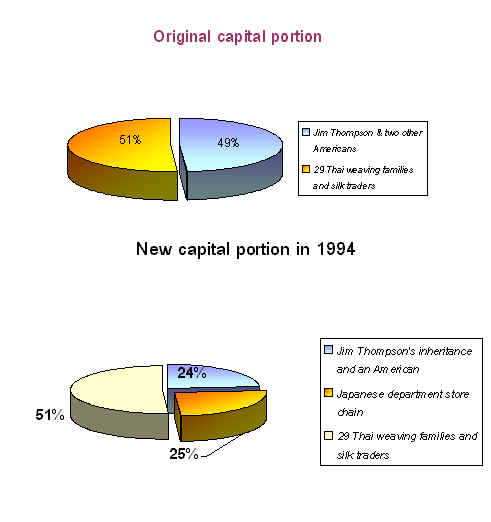

Capital portion

In 1994, the widow of one of the original American shareholders had sold her 25 percent stake to a large Japanese department store chain for a price reputed to be $25 million. This amount was two–time higher than the book value. (25% of shareholder in 1993 was equal to 1,279 mil bht/25.28 bht/$ *25% = $12.65 mil)

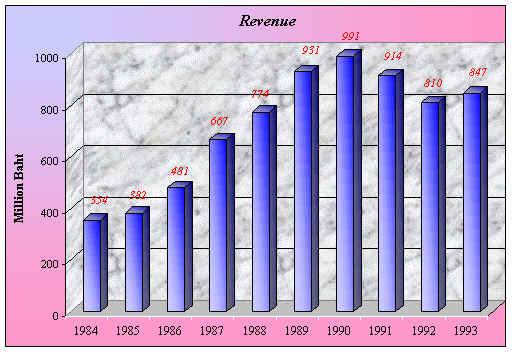

Revenue

Revenue growth

The revenue growth had decrease trend since 1990. It was because of dropped in company’s overall retail sales when number of tourists visiting Bangkok declined under various reasons follow:

- Rapid industrialization

- Auto congestion

- Air pollution

- Aids

However, the company’s revenue growth was increased again in 1993. The reason behind this came from the spectacular sales after opening new satellite retail outlet at World Trade Center.

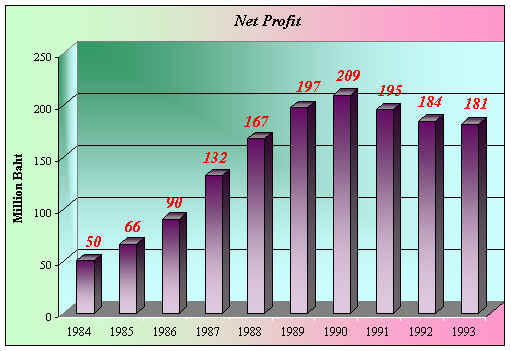

Net Profit

Net profit increased every year and reached its peak in 1990. After that, the company’s overall retail sales had dropped and caused the net profit declined from 1991 to 1993.

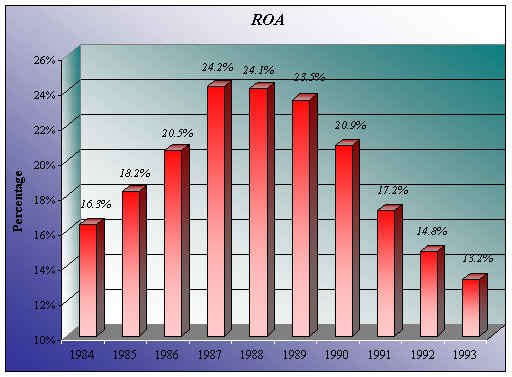

ROA

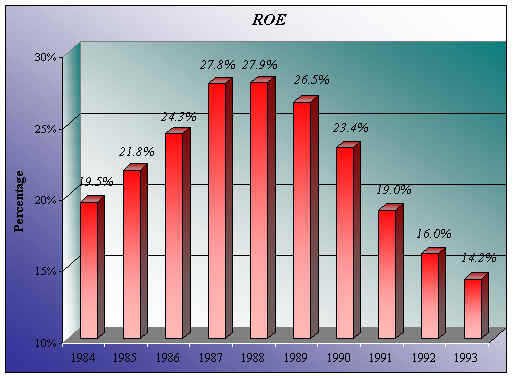

Since 1989, JT’s overall effectiveness of management in generating profits with its available assets had declined.

Since JT had resorted to no borrowing on long-term debt and also had low current liabilities, its shareholders’ equity was average 90% of total assets during 10 years. The ROE showed declined trend as same as JT’s ROA since 1989. It means that the return earned from the owners’ investment in the firm had declined.

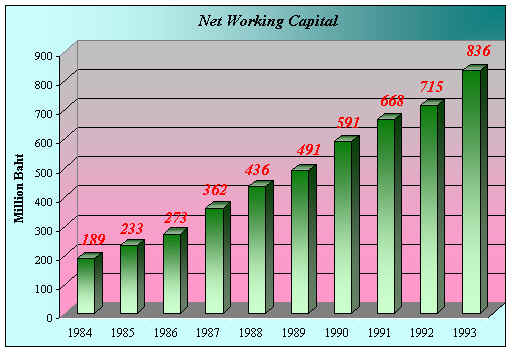

Net working Capital

During 1984 to 1993, the company had positive net working capital, it means that the firm had high liquidity and increasing year by year.

Strengths

1. JT was Thailand's leading retailer of native silk

The company had grown to become Thailand's leading retailer of native silk, commanding an enviable two-thirds share of the premium tourist market.

2. Ability to take advantage from fully integration

JT had gained competitive capability over its competitors after it expanded from retailer to fully integrated producer of native Thai silks. The advantages that the firm had received such as technology transfer, ability to control volatility in price, and secure supply.

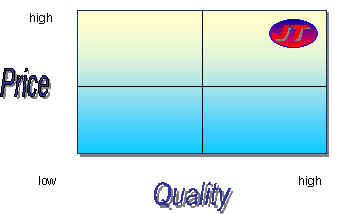

3. Reputation for superb quality and innovative design

The store’s reputation for superb quality and innovative design made it particularly popular among tourists and foreigners stationed in Bangkok. JT product have a good creative design, serving to differentiate the firm from competitors and enabling it to command premium prices.

4. Excellence leadership

Booth who is the company’s managing director played excellent leadership role to impress both customers and employees. He gave empowerment to the organization and usually uses consensus decision making. His role of interpreter and network relationship with knowledgeable foreigners helped the company obtain foreign expertise. Booth’s leadership had contributed to the company’s success.

5. The largest hand-weaving operation

Yarn produced by its spinning operation and that procured from outside sources was conveyed to JT’s weaving mill located in the town of Pak Thong Chai about 15 miles from the company’s sericulture operation. This facility was the largest hand-weaving operation in the country, JT also operated a satellite weaving mill. From the largest characteristic had led JT to take advantage of economy of scales.

6. Progress on the technical front

JT had made progress on the technical front than its competitor such as in sericulture operation. JT had succeeded in producing several highly resistant crossbreeds of Chinese white and Thai yellow silkworm species.

7. Using retained earning as its source of fund

JT’s growth over the years had been financed largely by R/E which is the cheapest of the source of fund compared with other source of fund such as short-term or long- term debt or issue new stock.

8. Attractive store decoration

It’s flagship store, located next to its headquarters building in the heart of Bangkok’s commercial district, was designed to resemble a Siamese palace of an earlier era, with several tiers of sloping tile roofs. The building’s sumptuous interior was lined from floor to ceiling with teak shelves containing the largest selection of Thai silk fabric in the world.

9.Technology transfer

Technology transfer to secure initial technology for its printing plant. Its joint venture partner in this activity was a small West German textile printer with a reputation for very high quality. This firm had helped select initial equipment for the printing venture, arrange factory layout, and oversee early start up. JT had used to obtain foreign technology was to send company personnel abroad for technical training, and JT had used to obtain technology from abroad was to bring foreign experts to Thailand to train company employees.

1. Limitation of distribution channels

Jim Thompson has only 5 retail outlets, JT's shops were all located in Bangkok, and when its revenue and profitability were falling. JT faced with big problem because JT sales its product especially in owned retail outlets. Therefore, JT has limit in distribution channels and did not expand market to other channels that can gain more revenue.

2. Narrow segment

In the area of marketing, JT's marketing skills are not yet very well developed, especially in home furnishing market. JT focused on narrow segment such as foreign tourists and when retail sales declining, they faced with big problem.

3. Weaker garnering demand than rivals in home furnishing market

In home furnishing market, JT can not capture this market when compare with competitors. Numerous suppliers, many larger and more highly automated than JT, served the market. JT have garnered very little of home furnishing market.

Opportunities

1. Free of controls on private enterprise

The economy is relatively free of controls on private enterprise that are common in other developing countries. The Industries Promotion Act of 1962 provides companies operating in designated industries quarantees against nationalization, and exemptions from import duties, export duties, and many taxes. Therefore, JT can freely operate in its business.

2. Low risk of Thai Baht

The Thai “baht” is freely convertible into foreign exchange. It’s value against the dollar has remained very stable over a long period of time.

3. Growing in Asian market

JT’s export sales were handled by commissioned agents located in other countries. Most export sales consisted of home furnishing fabric. JT can gain more markets by entering to potential market as Asian Market where are growing

4. Emerging new tourist spot in upcountry

Phuket as a location were growing very rapidly. Phuket were still relatively unspoiled. More Japanese are bypassing Bangkok and taking advantage of the increasing number of direct flights to Phuket. Japanese tour operators note that the environment-and-safety conscious Japanese are showing strong sign of general disgust with the capital city’s traffic problems. Strong marketing by new Phuket developments like the Pacific Islands club and the new Sheraton Grande are also diverting the Japanese from Bangkok.

5. Shopping was the tourist’s major activity

From percentage of total tourist expenditures in Thailand, the most percentage of tourist expenditure is shopping. In addition, shopping rate has also good increasing trend, that id 27.4% in 1986, 39.0% in 1990 and 42.8% in 1993

6. Expand in condominium demand

An increasing number of people were moving from the outskirts of Bangkok to downtown condominiums near their work locations to avoid traffic jams during commuting hours. A heady construction boom was taking place in the city, and new units being built needed furnishing . And JT’s reputation for creative design and good quality were highly prized by interior decorators, who acted as prime decision makers in the market.

Threats

1. Adverse Developments in Bangkok

Recent developments were threatening to undermine this hard-earned success, however. Bangkok’s increasing auto congestion, escalating air pollution, and soaring AIDS infection rate were causing foreign tourist-JT’s primary customers-to avoid the city as a travel destination. Rapid industrialization was destroying many of the charms which once attracted tourists to the city.

2.Volatility of raw material

Shortages were caused in part by a decline in the acreage that Thai farmers devoted to mulberry cultivation. Total acreage devoted to this end fell from about 60,000 hectares in the mid-1970s to less than 40,000 hectares in the early 1990s. This decline was caused by migration of villagers from the depressed silk-producing regions in the Northeast to Bangkok in search of higher-paying jobs and by conversion on the part of many remaining farmers to other crops. Since mulberry leaves constitute a silkworm’s chief diet, declining mulberry cultivation led to reduction in output of raw Thai silk.

3. Recession in Japan and Europe

Recession in Japan and Europe which supplied a large proportion of JT’s customers, also played a role.

4. Unforeseeable events

With the Iraq war and a brief military coup occurring in Bangkok in 1991, caused the number of tourists visiting Thailand to decline that year for the first time in many years.

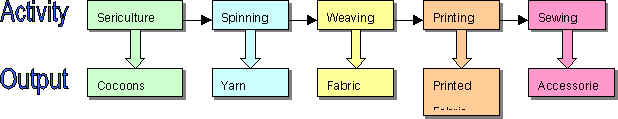

Jim-Thompson had become the country’s only fully-integrated producer of native silks, so its company value chain should considered cover to both upstream value chains i.e. the activities of supplier and down stream value chains i.e. the activities of forward channel allies and strategic partners.

Upstream Value Chains

- JT had contract with approximately 1,500 farming families in a broad area surrounding its sericulture facility to raise silkworm eggs, which buy from JT, to the cocoon stage and sold cocoons back to JT. This can help JT to reduce cost of operate its own larger rearing house and the cost of hiring many workers.

- JT’s sericulture operation had succeeded in producing several high resistant crossbreeds of Chinese white and Thai yellow silkworm species, which results in help the contracted farming families improving production yields.

Company Value Chain

Primary Activities and Costs

- JT purchased large quantities of silk cocoons from suppliers located in Thailand, some part from contracted farming families in a broad area surrounding its sericulture facilities which buy silkworm eggs from JT and raise to the cocoon stage and sold back to JT. This can help JT reduce cost of raw material and

- JT also purchased large quantities of cotton fabric from outside sources and sold under its own brand.

- Yarn, which is raw material for weaving operation, is obtained from its own spinning operations about 22 % and the rest procured from outside sources, largely imported from China.

- JT had established remote buying stations in various parts of Thailand, this remote station can help JT to deal with increasing shortages of domestic raw silk.

Sericulture

- JT cultivated mulberry trees that used to feed silkworm on a 900-acre plantation at the upper end of a farming valley in Pak Thong Chai. The location of plantation area provide the advantage of cheap land cost and help reduce transportation cost since it’s located near its sericulture facility.

- In its sericulture operation at Pak Thong Chai, JT has settled the large rearing house, which use to grow up the silkworm and sale some part of eggs produced by these silkworms to the contracted farming family. And the rest was raise in JT facility to the cocoon stage which can supply JT about 66 % of its internal demand.

- JT operate its sericulture business on a wholly owned basis.

- This operation gives the company protection in the event raw silk prices suddenly rise.

Spinning

- JT operates its spinning facility adjacent to its sericulture operation. This activity utilized fourteen automated spinning machines and employed 250 operators.

- JT operate its spinning operation on a wholly owned basis.

Weaving

- JT had operated its owned weaving mill on the wholly owned basis located in Pak Thong Chai, where many of its contract weavers lived and near its sericulture and spinning operation. This weaving mill is the country’s largest hand-weaving operation. In addition JT also operated a satellite-weaving mill in a nearby village. Total capacity of this two weaving operation was 593,000 meters of fabric in 1993.

- JT also operated several power looms at its Pak Thong Chai facility, mainly to weave cotton fabric with total capacity of 38,000 meters of fabric in 1993.

Printing

- JT operate the printing plant in joint venture with West German texttile printer, the plant located near Bangkok. This plant was installed both hand printing table and state-of-the art machines for high-speed printing. Later JT was planning to transfer its printing plant to new location adjacent to the company’s weaving mill in Pak Thong Chai, this moved would enable the company to avoid problems arising from increasingly stringent water pollution in the Bangkok area.

Sewing

- JT had joint venture sewing operation located in Bangkok, which produce more than 500,000 different pieces of merchandise.

JT fully integrated operation provide the advantage in reduce cost since the input of each operation can obtain from internal sources, further more JT can control the quality of its product throughout the whole process.

- JT retail stores were well stocked store always contained plenty of merchandise for tourists to make their selection. This is the nature of business of merchandise retailer that needs to stock a lot of inventory in the store. This can incur high inventory cost to JT and also the store space rental fee.

- For the home furnishing market JT sales its fabric directly to designer of the project and delivering them directly from JT’s plant.

- JT’s had commissioned agents located in many foreign countries to be its distributors in foreign countries.

JT’s sales had participate in three major mkt.

Retail Sales

- JT operated five retail outlets, all located in Bangkok. It’s stores was designed and decorated in old Siamese style. The flagship stove located next to its headquarters building in the hearth of Bangkok’s commercial district, three were located in the lobbies of luxury hotels, and the last was locate in Ground floor of Bangkok’s World Trade Center.

- JT’s retail merchandise was typically priced 15% to 20% above levels charged by rivals.

Home furnishing Sales

- JT sold its fabric directly to local hotels, office buildings, condominium and housing projects. Its sales effort was focused mainly on interior designers who were chief decision-makers in this market

- A sizeable portion of these sales consisted of cotton fabric, the bulk of which JT purchased from contract suppliers and sold under its own brand.

Export Sale

- JT’s export sales were handled by commissioned agents located in more than 24 countries throughout the globe. It’s had an international advertising program, and plan to open showroom in London; and plan to expand market to several growing Asian markets.

Support Activities and Costs

- JT’s sericulture operation had succeeded in producing several high resistant crossbreeds of Chinese white and Thai yellow silkworm species, which results in improving production yields.

- JT had been brought in and improve its technologies by form joint ventures with foreign firms that expertise in particular area to gain the technology transfer from those firms.

- JT had not merely duplicated technology brought in from the outside, but had often significantly adapted it to the company’s special needs.

Design

- JT had the reputation of creative design, serving to differentiate the firm from competitors and enabling it to command premium prices. The design department was functioned to developing new fibers, new color formulations, new weave patterns, new print designs, and new garments. JT also brought in a weave designer from Ireland and print specialist from Taiwan to joined to the group.

- Send company personnel aboard for technical training, e.g. JT employees had been send to China to receive training at the Chinese Sericulture Research Institute, and employees who hired to operate the company’s spinning machines had also send to China for technical training.

- Bring foreign experts to Thailand to train company employees, e.g. expert from China’s Sericulture Research Institute had made numerous trips to Thailand to train JT employees, and several technician were in Thailand as late as 1994 providing such training.

- JT had maintained the network of relationships with knowledgeable foreigners, which helped the company obtain foreign expertise. JT also forming strategic alliances and collaborating with many strategic partners e.g. forming jointed venture with a German company, Rohleder GMBH

Since JT was the fully-integrated producer of native silks, the company can strengthen its competitive position in term of:

Due to each successive step into silk production had obliged JT to acquire new technology. JT used the expertise in different area of production.

JT had not merely duplicated technology brought in, but had often significantly adapted it to the company’s special needs. The knowledge was accumulated over time and was made continual modifications by JT. For example: microprocessor to control the process of dyeing had been imitated by JT in reeling and weaving operations. Everyone are forcing to continually improve, to compete with itself for greater efficiency and higher reliability.

Bill Booth setting a good model for employee in arriving early and leaving late. He spends much time visiting JT different operations, raising questions, providing information every where he goes and empowering in term of decision making.

Pichet (Deputy Managing Director) and Surindr (Production Division Manager) approach their jobs with a great deal of independent judgment. Their strong roots in Chinese culture, which encourages more independence of mind, fosters the quality that helped them develop into very capable, imaginative managers.

From the original base of merely retailing products produced by others, Jim Thompson had expanded the firm’s range of activities backward into sources of supply to become the country’s only fully-integrated producer of native silks (participating in all stages of the industry value chain). A firm accomplished vertical integration by established partnership with a company already performing the activities and wholly-owned basis in some activities.

Step in Expansion

Under Booth’s direction, JT expanded into each successive stage of the silk production process. The company integrated backward by using different form of expansion (see Exhibit ##).

Year of expansion |

Activity |

Form of expansion |

Location |

1974 |

Sewing business |

Established a sewing venture in partnership with a prominent Thai businesswoman. |

Bangkok |

1978 |

Printing business |

Acquired a printing plant in partnership with a West German textile printer. |

Bangkok |

1979 |

Weaving business |

Establish a wholly-owned basis. |

Northeastern Thailand |

1988 |

Sericulture & Spinning |

Establishing operations on a wholly-owned basis |

Northeastern (near its weaving mill) |

Factors motivating JT’s expansion into production

The problem occurs while JT tried to expand its home furnishing business because contract weavers are sometimes unreliable about meeting delivery schedules. Delay in receipt of wall covering or upholstery material can postpone occupancy of a new building, and late occupancy imposes a serious cost on a building’s owner. By bringing weaving under our direct control JT have significantly improved its ability to deliver on time.

- Migration of villagers to Bangkok in search of higher-paying jobs.

Conversion to other crops such as cassava.

- The freed from Chinese government constraint to allow silk producers to cultivate other lucrative crops such as fruits and vegetables.

- Prices on the world market climbed

Due to Thai silk industry was dominated by very small producers employing traditional handicraft methods. The technology employed was generally quite rudimentary. These original producers lacked resources to underwrite significant improvement in technology. Therefore, JT had undertaken production in part to bring its substantial resources to bear on this problem.

The Strategic Advantages of Vertical Integration in JT

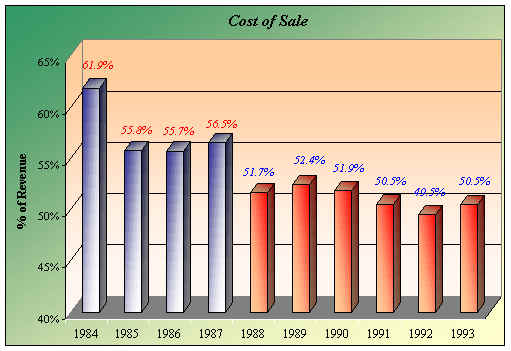

After the company already fully integrated in 1988, JT’s cost of sales had declined from 55.7-61.9% to 49.5-52.4% of revenues.

JT used differentiation strategies as its competitive approach. Creative design was frequently mentioned by JT managers as one of its primary strengths, serving to differentiate the firm from competitors. The design department employed more than 30 people devoted to developing new fibers, new color formulations, new weave patterns, new print designs, and new garments. In addition, a weave designer from Ireland and a print specialist from Taiwan had recently joined the group.

This successful differentiation allows a firm to

- Command a premium price for its product

JT’s retail merchandise was typically priced 15 percent to 20 percent above levels charged by rivals. For example, the prices of its product in 1994: printed neckties ($35.70), head scarfs ($31.00), printed cushion covers ($18.90) and printed silk napkins ($11.00).

- Gain buyer preferance to its brand

The company’s reputation for superb quality and innovative design made JT particularly popular among tourists and foreigners stationed in Bangkok, two groups able to afford its prices, which were well above those of most local competitors.

Differentiation in JT exists in “Product R&D activities” that aim at improved product designs and performance features, wider product variety.

JT has formed cooperative partnerships with other companies to complement their own strategic initiatives and strengthen their competitiveness in acquiring new technology. Generally in silk production, needed expertise was not available in Thailand. To form joint ventures with foreign firms is one approach that the company used to secure foreign technology. For example;

James Thompson

The fate of an American millionaire with a mysterious past who was known as the “silk king of Thailand” remains as much a mystery today as when he vanished 30 years ago. On a warm Sunday afternoon in March 1967, Thompson disappeared whilst on holiday in Malaysia’s Cameron Highlands. To this day his fate remains unknown he simply walked out of the cottage where he was staying, and never came back. Even before he vanished, the life led by James H.W. Thompson had the makings of legend. The scion of a wealthy Delaware family, he graduated from Princeton in 1928, and later studied architecture at the University of Pennsylvania, practicing professionally for a time before enlisting in the US Army in 1941.With World War Two came formation of the Office of Strategic Services, forerunner of the Central Intelligence Agency. As an OSS operative, Mr. Thompson served in North Africa and Europe before being trained for behind-the-lines action in Thailand. Mr. Thompson determined to make a career in Thailand following cessation of hostilities. He settled in Bangkok after the war, first helping to revive the famed Oriental Hotel.

During exploratory visits to Thailand’s isolated and impoverished north-east, Thompson became interested in the almost extinct cottage silk industry, and began making enquiries. In 1948, he launched the Thai Silk Co, which breathed new life into a dormant industry that had been overwhelmed by cheaper textiles from Europe and Japan.

In term of leadership role, Mr. Thompson plays as capabilities builder and creative person. With an architect’s eye for design and color, Mr. Thompson improved the dyes and taught hand-weavers from the village of Ban Krua to produce brightly patterned silks under strict standards for foreign buyers. He prospered and became one of the best known Americans in Asia. In addition, He assembled a home mostly of teak out of six smaller, old-style Siamese houses from Ban Krua and filled it with ancient stone statues, Chinese porcelains and a priceless sixth-century Buddha. Built to house not just Thompson, but also his unique collection of Southeast Asian art, the house today functions as a museum, and is open to the public. Now a museum, the palatial building with its art, rare silks and antiques is a must-see for tourists.

Bill Booth

Executive leadership was another factor cited as critical to the Jim Thompson Thai Silk Company’s success. A strategy manager has many different leadership roles to play. Also Booth plays many leadership roles; sometimes he is best to be perceptive listener and a compromising decision-maker and sometimes he is a coach and advisor in the proper role. In term of leadership roles that dominate the strategy implementer’s action is follow.

Staying on top of how well things are going

To stay on top of how well the implementation process is going, Booth develop a broad network of contacts and sources of information, both formal and informal. The regular channels include talking with key subordinates, meetings, reviews of the latest operating results, talking to customers and so on.

In addition, Booth is also use the technique of “ managing by walking around” (MBWA) which is practiced in a variety of styles. Such as Booth arrives early, and leaves late-seven days a week-setting a good model for the rest of management team to follow. He spends much of his time visiting different operations, raising questions and providing information everywhere that he goes.

In term of the decision process, it had evolved under Booth’s leadership had contributed to the company’s success. He doesn’t try to make decisions for management team, but instead helps them think more clearly about the situations they’re facing. He empowered to senior manager. Management team include Booth spends a lot of time discussing an issue before a decision is made. Deliberations usually take place in the evening, often over drinks, and are very informal. This kind of setting helps generate a lot of good ideas. It also provides plenty of opportunity for potential obstacles to surface. When obstacles emerge, they go back to the drawing board to study details more carefully. When a decision finally emerges, they have generally thought it through very thoroughly.

Other Booth’s role, Booth’s interaction with staff and others showed him performing a variety of different roles in managing the company. Booth frequently brought together key people whose interaction could benefit the company. He performed this role, for example, during a day-long visit to the company’s production operation in Pak Thong Chai. Accompanying him on this visit were young Thai male named Tamrong who managed the company’s printing joint venture, Czerny, and Surindr. During discussion in the logistics, Booth would interject a brief clarifying comment-in English to Czerny, in Thai to the other two. Also accompanying Booth on this trip was the representative of a major Brazilian raw silk producer. During his inspection, Booth played the role of interpreter. Another role, which Booth performed on a regular basis, was that of gracious host. He took obvious pleasure in treating visitors that included department managers, lower-level employees, suppliers, customers, and directors to lunch and to cold beverages and appetizers and so on.

Moreover, there is interested thing, Booth pointed to the exceptional capability of his senior managers, all of whom were Thai. The textile industry is considered low-tech by most Thai managers-not a very exciting area to be in. Because of this stigma, it’s hard to attract really good managers to a company like JT. Another problem is the reluctance of many Thai managers to question higher ups. Because of this trait, even individuals who are very qualified technologically often don’t have the independence of mind to become really effective managers. They have been very lucky to avoid these difficulties. Pichet and Surindr, for example, approach their jobs with a great deal of independent judgment. This quality has helped them develop into very capable, imaginative managers. Perhaps their strong root in Chinese culture, which encourages more independence of mind, fosters this quality. It might also come from the fact that the three joined the company at about the same time and have grown up here together, so JT management just naturally consider themselves as equals.

JT has an ability to harmonize the prominent point of Thai Culture, Chinese culture, and Western culture to create their own corporate culture.

Characteristic of Culture |

Corporate culture |

|

Thai Culture |

|

|

Chinese Culture (From management team) |

|

|

Western Culture & Leadership style |

|

|

According to the threatening from the recent development of Bangkok in term of increasing auto congestion, escalating air pollution and soaring AIDS infection rate, foreign tourists who are JT’s primary customers has avoided the city as a travel destination. This situation had to change in demand condition. From the past, JT’s big challenge was to produce enough to meet demand because the demand at its retail store was so strong. With retail sales declining today, JT experienced a new challenge to find new demand to meet its efficiency production. Since JT’s shops were all located in Bangkok, its revenue and profitability were falling.

Seeking the strategic planing to reduce the company’s dependence on Bangkok’s tourist market that is the major cause of problem in declining revenue and profitability.

Evaluation in the option for improvement

|

Cons |

|

|

|

Cons |

|

|

|

Cons |

|

|

To compete more effectively in the home furnishing market, JT would need to significantly improve its high-speed mechanical weaving capabilities.

Rohleder (the world’s eighth largest, and Germany’s second largest, manufacturer of upholstery fabric) was interested in establishing its own weaving facility in Asia in order to gain access to low-cost Asian labor and to better serve its growing base of Asian partner, and inquired wheather JT would consider joining it in constructing a jointly-owned weaving mill in Thailand.

While Rohleder’s skill in mechanical weaving – the very capability JT needed to improve its position in the home furnishing market – made the proposed venture with Rohleder attractive.

|

Cons |

|

|

Objective:

Stimulate sale volume in three major markets including Retail sales, Home furnishing and Export.

We select this option to be the first priority because these two areas were growing very rapidly. JT should capture this opportunity before the fascinated of these places will be destroyed.

In addition JT could consider to open the retail shop in other attractive location of Thailand that have the potential of tourism growth such as Chiang Mai and Lampang.

We select this strategy it needs not much investment.

Expand sales to the domestic home furnishing market especially in the section of increasing capability in marketing.

JT should spend more effort in term of marketing. In home furnishing market, the key purchase considerations were design, price, and delivery. Thus JT should emphasis on these 3 points. For example:

Objective: